-

Allround Lightweight Steel Scaffolding

-

Allround Lightweight Steel

-

- Lighter and stronger (World first!)

- Higher capacity

- Faster handling, erection and dismantling

- Lower transport costs

- Fully compatible

-

-

Lighter and stronger (World first!)

Layher’s Allround Lightweight (introduced 2013) is a lightweight variant of the Allround Scaffolding System.

Using a specially developed steel, (a world first), Allround Lightweight significantly reduces the weight of components without compromising the strength and versatility that are the hallmarks of the Allround Scaffolding System.

The high tensile strength of the new steel enabled designers to reduce the wall thickness of Allround Lightweight tubular components, reducing their weight by up to 14 percent.

The lower weight translates to faster, safer and more efficient component handling. Allround Lightweight is rapid to assemble and disassemble, and more economical to store and transport, which means greater returns for your business.

Not only that, lower overall weight means less load from the scaffolding system itself, so Allround Lightweight enables you to create higher scaffolding structures, or support larger loads at the same height.

Layher Lightweight is a great product. It’s certainly noticeable, the decks, standards and obviously the ledgers are considerably lighter to carry. Take that back to a truck loading situation where NZTA are a lot more stringent on truck pullovers and ensuring that we’re not loaded over capacity is pretty important to us. So it’s really beneficial.

Chris Douglas, Northland Scaffolding

-

Allround Lightweight offers significant savings in transportation -

-

Shipment, erection and dismantling account for the lion’s share of costs. Which is why Allround Lightweight delivers such a rapid return on investment. Typical cost breakdown based on five deployments annually.

-

-

Layher Allround Lightweight Steel Scaffolding -

-

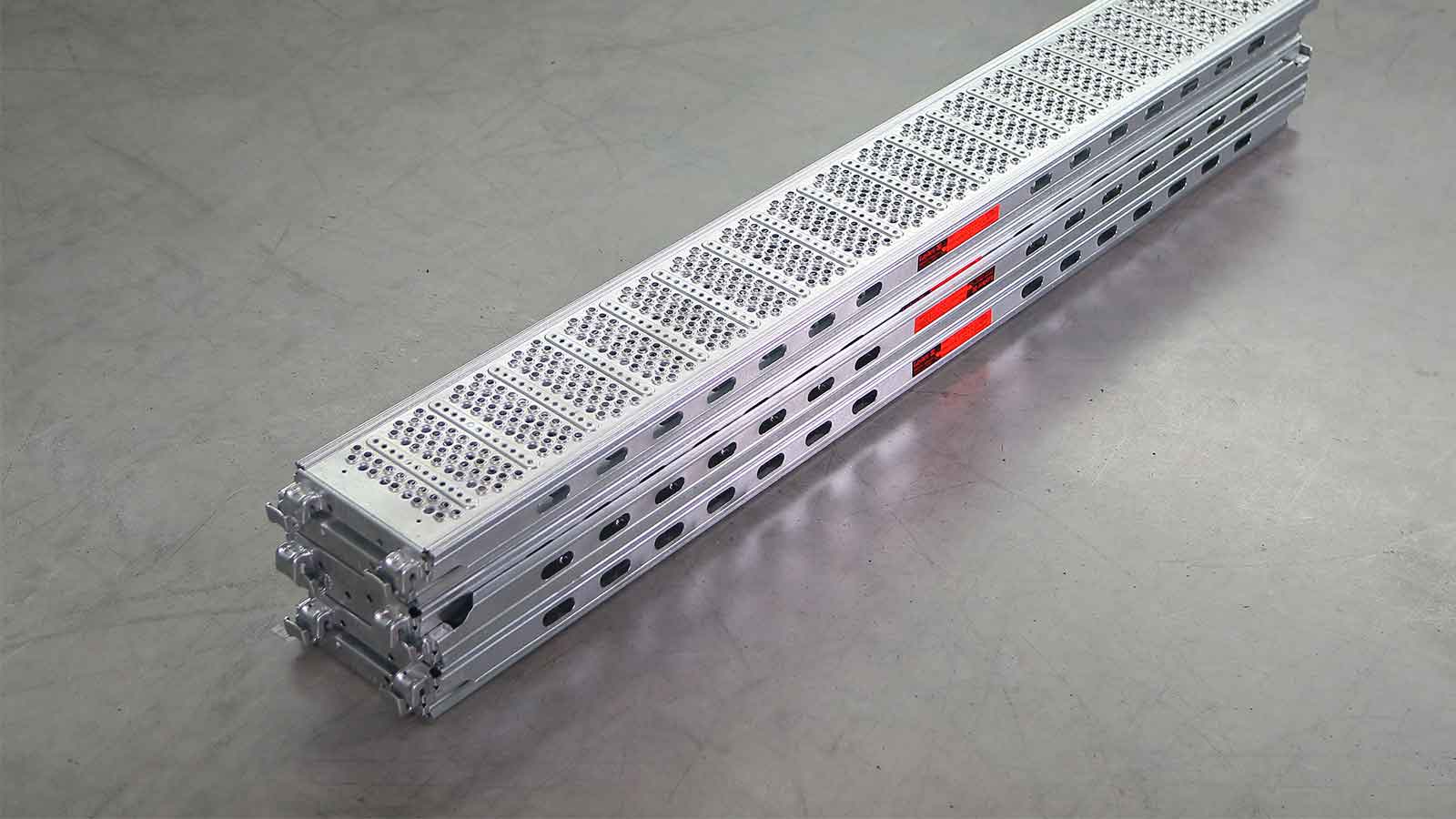

Steel deck lightweight

Layher Steel Deck Lightweight A good product is now even better! This is exactly what‘s been achieved with the steel deck lightweight.

By using higher-tensile steel grades, a thinner material and an innovative combination of profiles and material concentrations at structurally relevant areas, it has proved possible to reduce the weight of our steel deck, already established in the market, by up to 10 % – while retaining its high load-bearing capacity.

The latest product in the Layher Lightweight family is distinguished by:

- efficiency during transport and assembly

- versatility, durability and strength

- practically-minded safety.

The boys love the new Lightweight decks, plus it helps us save on the transport.

Phil McCue, Alphies

-

Steel Deck Lightweight

We opted to use LW Allround on this birdcage spanning 16m over a dive pool 28m long. The scaffold was built over nine consecutive night shifts, LW significantly reduces fatigue on larger projects. LW gear is much easier to handle notably the decks where everything needs to be passed up.

Jarrod Radcliffe, South Pacific Scaffolding

-

Higher capacity

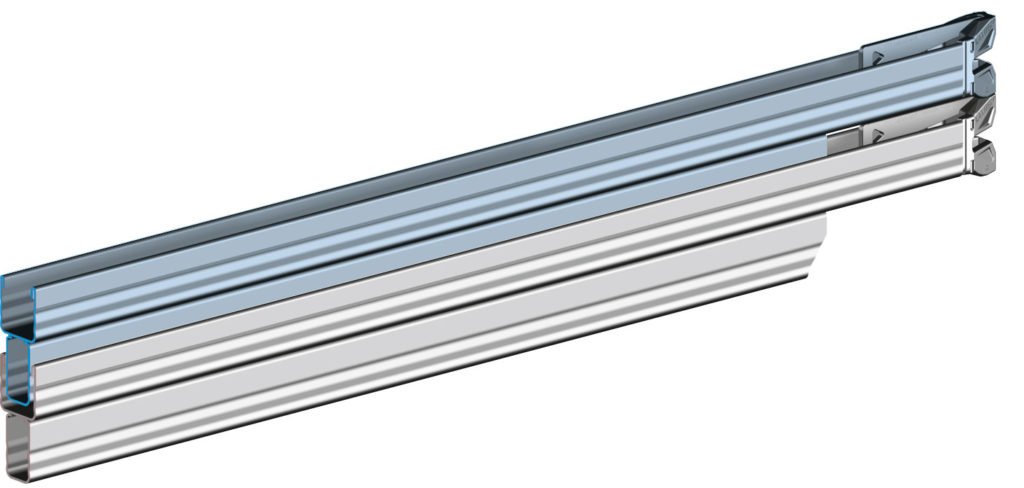

Increased headroom with new Allround Lightweight U-ledger Despite thinner tube walls and lower component weight, Allround Lightweight makes no compromises when it comes to robustness. With a bending strength 24% greater than traditional steel scaffolding tube, Allround Lightweight is a highly rigid and solid solution that offers a range of strength-related benefits, and in some cases an opportunity to reduce the number of components.

High tensile steel also doesn’t require the same degree of reinforcing eg: in transoms. This means Allround Lightweight components can be designed and built using less raw material and in some cases with double the load capacity compared to traditional steel components.

-

-

Space savings with stackable Allround U-ledger lightweight -

-

Faster handling, erection and dismantling

Lighter is faster. Some 80% of the total cost of scaffolding is attributable to loading and unloading trucks, transportation and labour. Layher Lightweight’s reduced wall thickness means a greatly lowered component weight and cost savings for your business.

-

Reduced wall thickness means a greatly lowered scaffold component weight.

Photo credit: Nayland Scaffold

-

The boys noticed the reduced weight in the yard immediately. I can only say positive things about Layher Lightweight.

Evan Wheeler, Counties Scaffolding

-

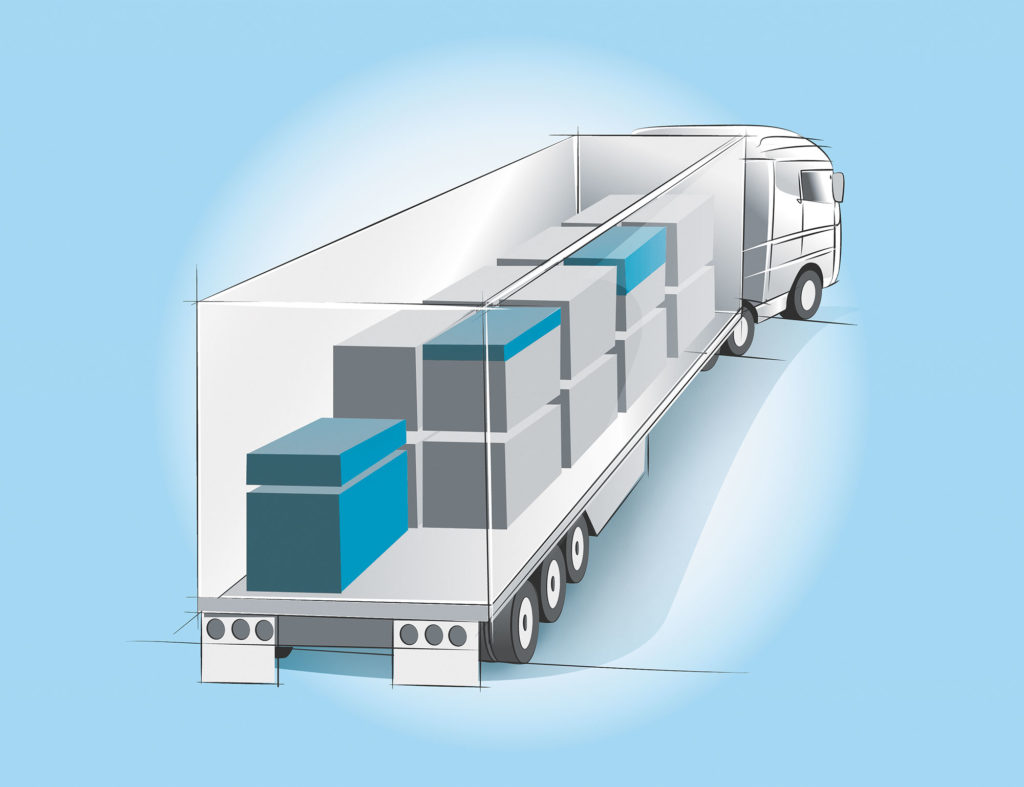

Lower shipment costs

A truck‘s maximum permissible payload is determined by weight, not volume. Therefore Layher Lightweight components mean additional savings when it comes to shipping scaffold to and from the construction site. For example, with a truck plated to carry a maximum load of 23 metric tons, you could transport approximately 6,400 m³ of birdcage scaffolding. With Layher Lightweight components, that figure rises to some 7,200 m³. That is 12 % more. That translates into fuel and manpower savings, and is better for the environment.

-

-

Fully compatible

And best of all, Allround Lightweight is fully compatible with components from the other Allround Scaffolding System variants, so you can continue to use all your existing Layher components.

-

-

The Benefits of Layher Lightweight

- Lower weight

- Enhanced load-bearing capacity

- Improved handling and safety

- Time-saving construction site erection and dismantling

- Cost savings through approximately 10% higher productivity

- Approximately 12% increase in truck payload by volume

- Fully compatible with Layher Allround components

-

-

-

Contact us now about Layher Lightweight Steel Scaffolding.