No trip hazard on suspended under bridge scaffold

Routine bridge maintenance work took less time thanks to the efficient Layher FlexBeam scaffolding. Master Scaffolding were contracted to provide access on a low bridge in Kaihere, Waikato. Shaun Mason, Managing Director, Master Scaffolding explains “we used Layher Allround scaffolding and Layher’s new aluminium FlexBeam on this bridge job. The Layher gear was faster and easier to assemble, when compared to using conventional methods.”

Less components, less transport

“The combination of Allround and FlexBeams allowed us to use less components, which meant less transport and greater weight savings” said Shaun. The scaffold was designed by Layher’s engineering team and allowed the Master Scaffolding scaffolders to preassemble sections of the scaffold in their yard prior to transporting to site. This in turn made assembly on site very fast and efficient.

3D scaffold design visuals

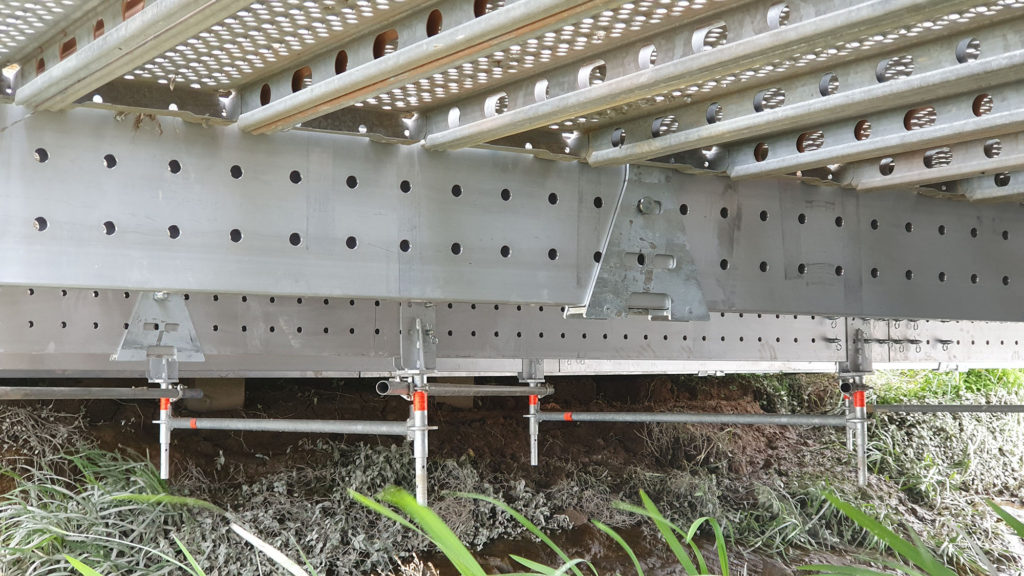

Shaun said “the scaffold design was so simple to follow, particularly with the 3D visuals. Our guys loved the simplicity of the FlexBeam. Our client was impressed with the speed of installation and dismantle, especially as this had reduced effect on traffic management.” Measuring 14 by 10 metres, the suspended scaffold provided contractors with a secure and stable working platform. The low bridge scaffold project on Kaihere Road lasted just 3 weeks.

Furthermore, Shaun’s client really appreciated the clean working deck with no trip hazards. This was achieved by placing U-profile decks on a series of FlexBeams. The FlexBeams were suspended from the bridge’s I beams using a combination of Layher components; beam grippers, adjustable suspended scaffolding chains and FlexBeam suspension shoes.

Thank you to Shaun Mason, Master Scaffolding, for the use of these photos.

-

Contact

Shaun Mason

Company

Location

Website

-

Components

Layher FlexBeam

Layher Allround Lightweight Steel ScaffoldingComments

The combination of Allround and FlexBeams allowed us to use less components, which meant less transport and greater weight savings.

Shaun Mason, Master Scaffolding

MORE SCAFFOLDING PROJECTS

Wallingford Bridge

Wallingford Bridge Strengthening L ocated in Hawkes Bay, the Wallingford Bridge project required smart, efficient scaffolding solutions to support essential strengthening and guardrail installation. Rocket Scaffolding, working with Layher systems, provided the access needed for contractors to safely complete their work under complex conditions. Safe, Practical Solutions for a Time-Sensitive Upgrade Todd Price of Rocket […] Continue reading

Approved Ponsonby Villa Repaint

Approved Scaffolding were requested to build a scaffold for a repaint on a Ponsonby Villa. The site was tight for Continue reading