-

-

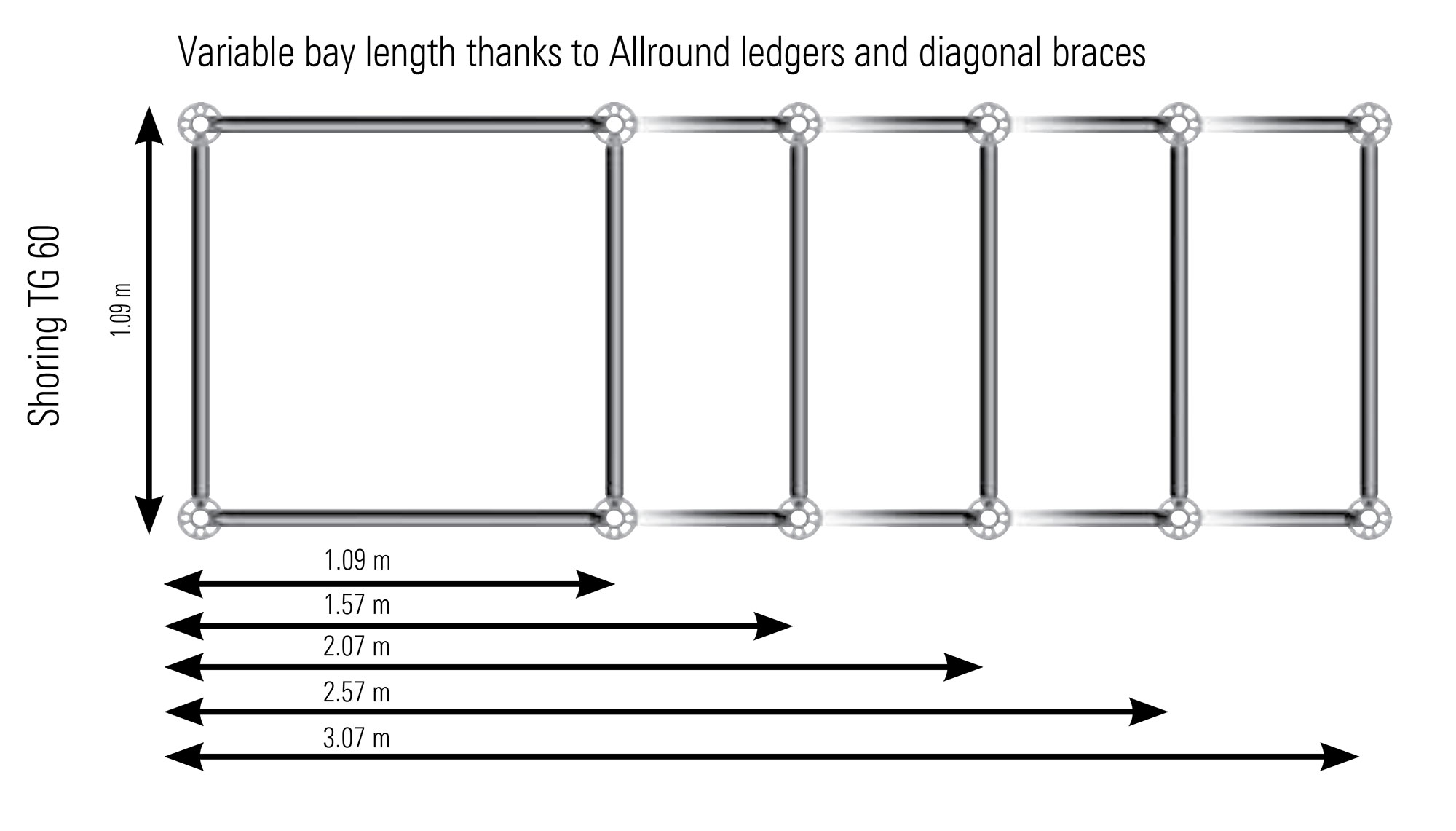

Shoring TG 60

-

- High-capacity propping

- Maximum flexibility (integrated with Layher Allround)

- Easily repositioned

- Multiple safety features

-

-

High-capacity propping

Layher’s Allround Shoring System, Shoring TG 60, is an extremely high-capacity propping solution.

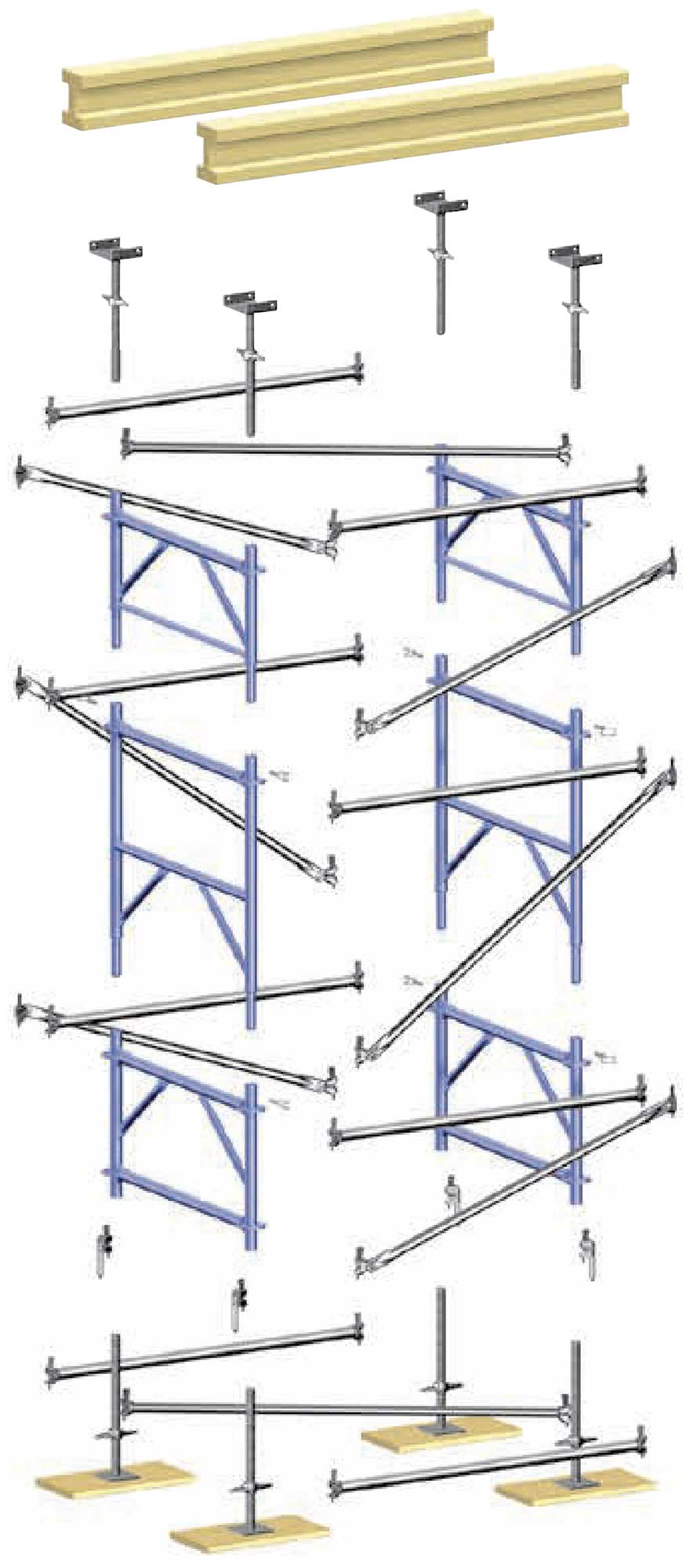

Each component in the Allround Shoring TG 60 frame is manufactured using lightweight, high tensile steel, and employs two integrated diagonal braces to increase strength and stiffness. The braces use a symmetrical design, so there’s no need to orientate them or install additional diagonal braces during assembly.

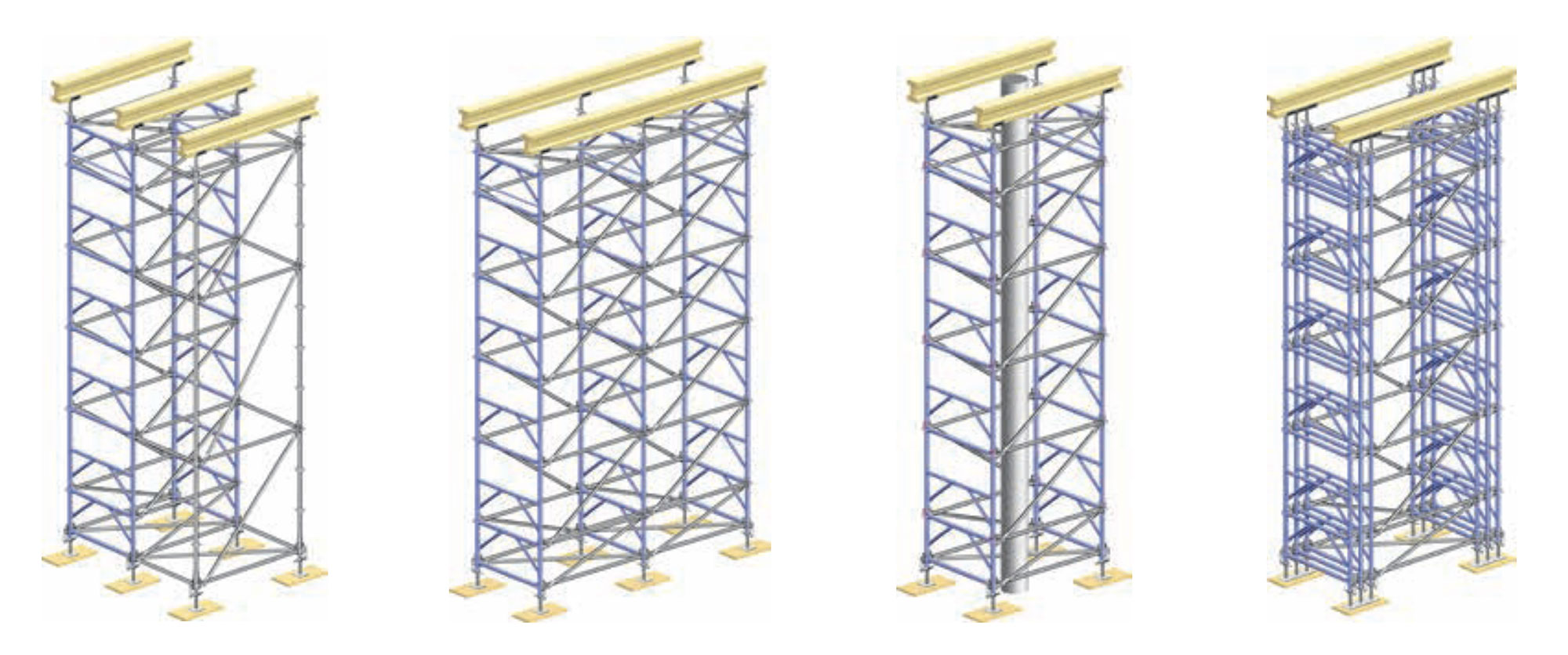

The components use the Allround Scaffolding System’s auto-aligning rosette or ring connector technology and integrated spigots allow you to secure the shoring frame using hinged pins, locking pins or bolts. For high-load applications, it’s possible to couple several Allround Shoring System frames together to greatly increase bending and vertical load capacities.

The result is a very capable shoring solution that reaches the heights you need while remaining sturdy and safe.

Every vertical standard can be loaded with up to approximately 6 tons.

-

Allround Shoring TG 60 propping frames -

Bundling frames increases load capacities of towers -

-

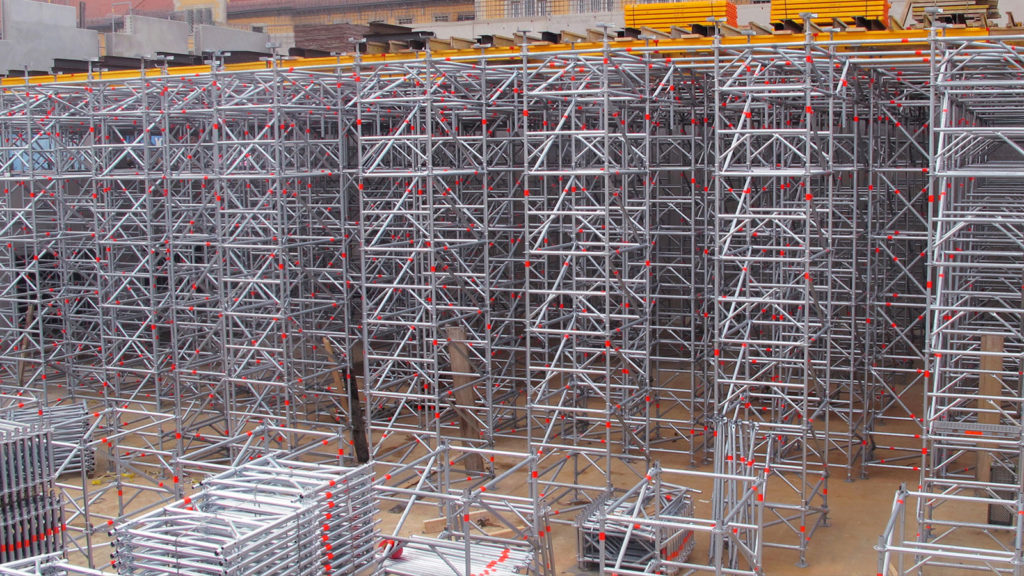

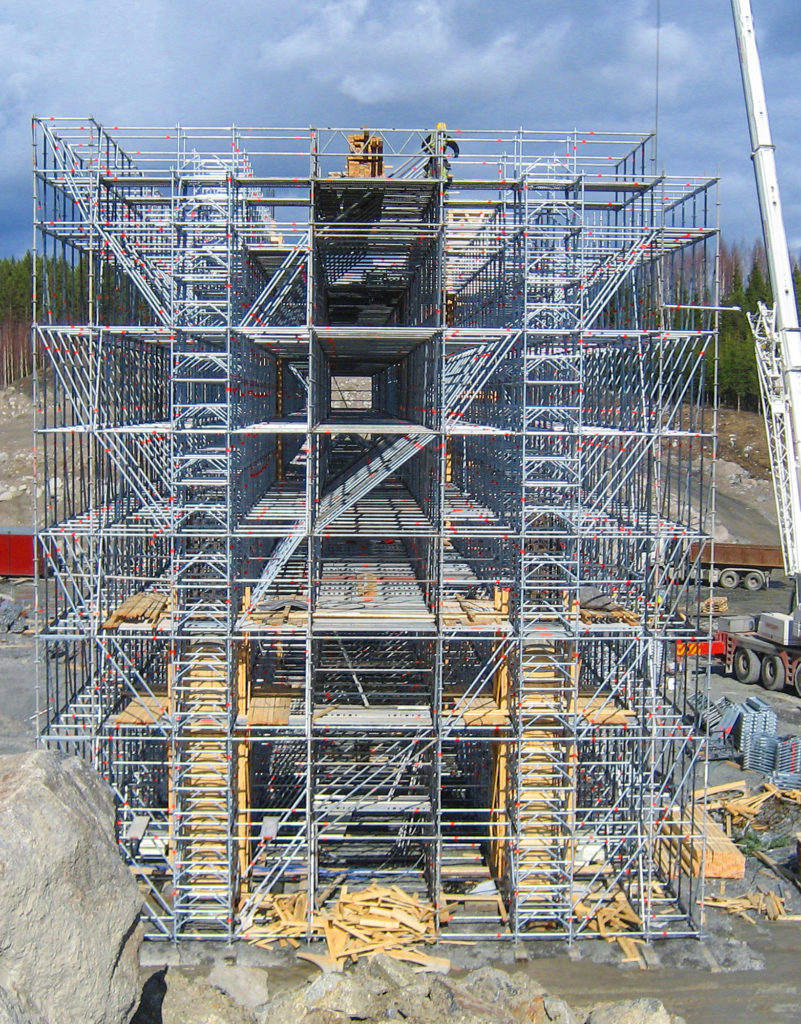

Allround Shoring TG 60 used together with formwork -

-

Maximum flexibility

Designed as an extension to the Allround Scaffolding System, the self-supporting Allround Shoring System combines versatility, robust design and easy assembly to create a highly configurable shoring platform that is efficient to handle and transport.

-

Lower number of parts, with integrated spigots -

Allround Shoring TG 60 seamlessly integrates with Allround Scaffolding

Allround Scaffolding designed around Allround Shoring TG 60 -

-

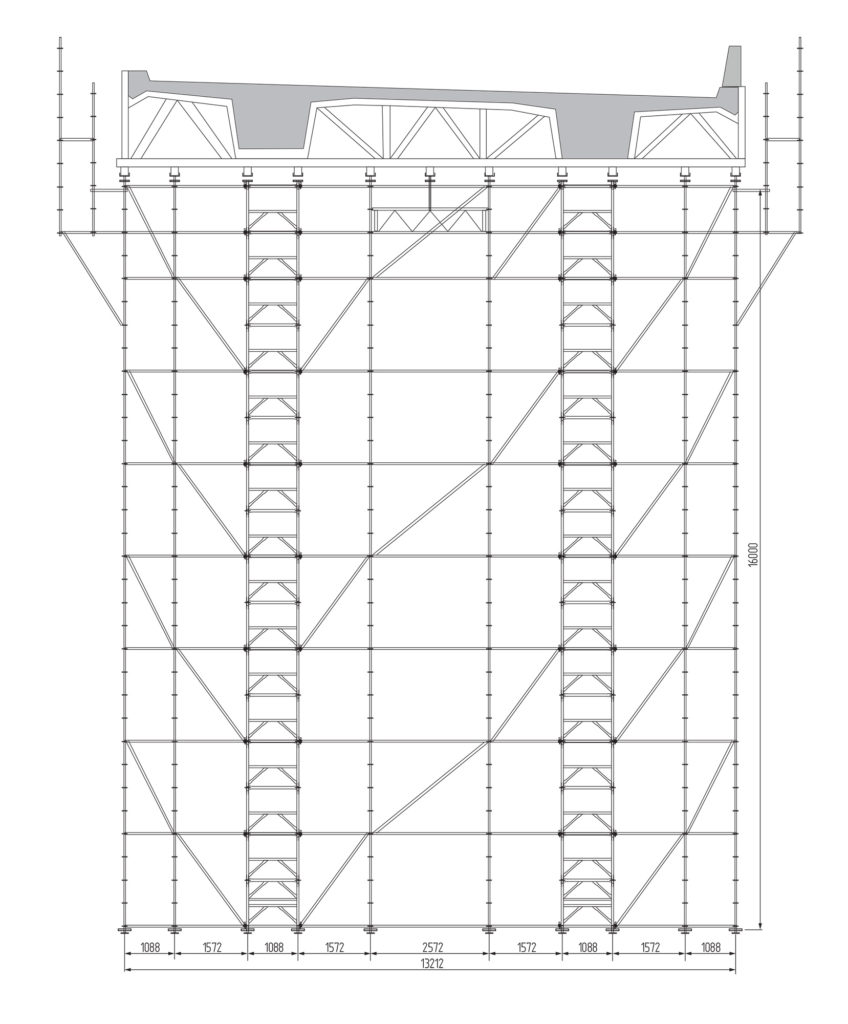

Allround ledgers and diagonal braces determine bay lengths -

-

Layher Allround Shoring TG 60 -

-

Easily repositioned

The Allround Shoring System’s strength and weight provides several assembly and deployment options.

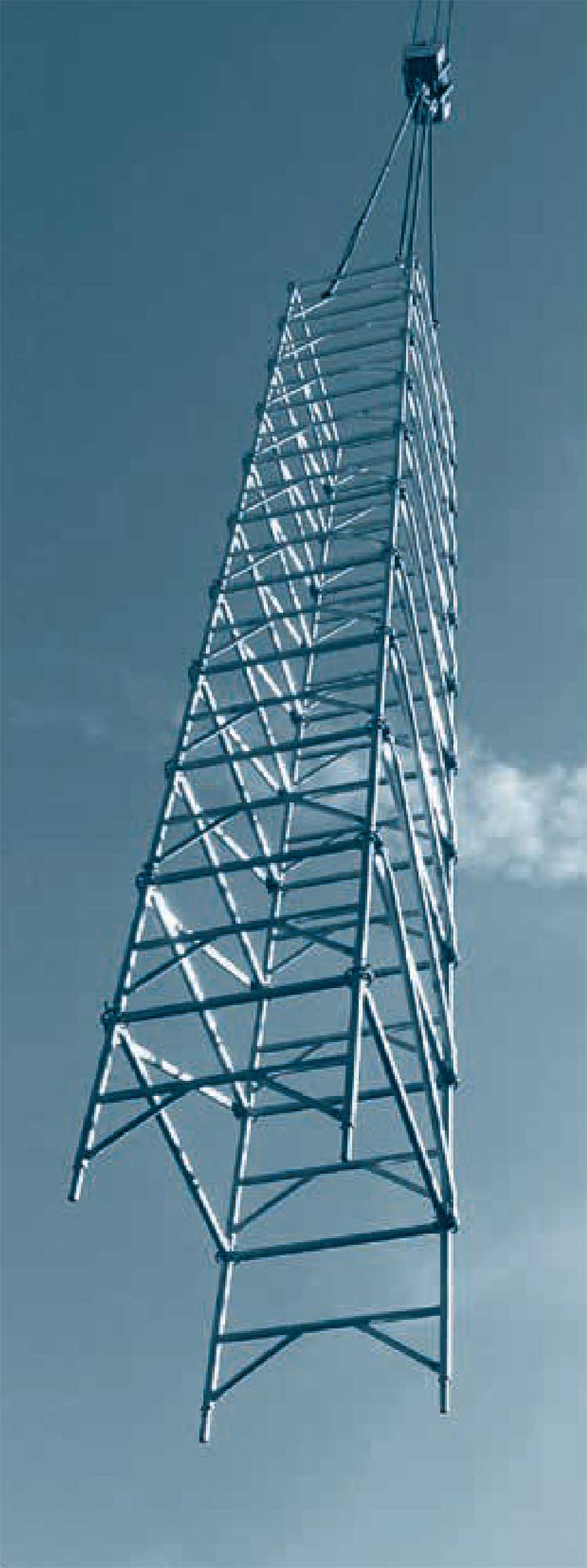

The system maybe be assembled in place or horizontally pre-assembled on the ground as a stand-alone structure, before being lifted into place by a crane or hoist.

Once erected, a fully assembled tower can be quickly and efficiently repositioned using castors – no disassembly required. It’s even possible to move entire tower groups in a single operation.

Quickly and easily reposition with castors

-

Build safely on the ground and crane the whole shoring tower into position -

-

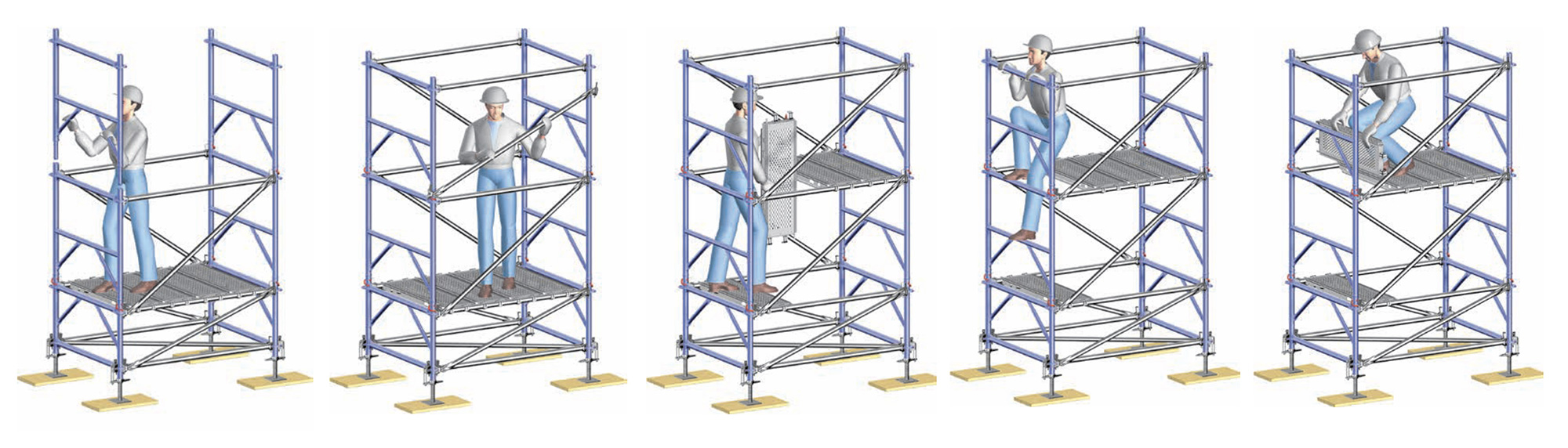

Multiple safety features

The Layher Allround Shoring TG 60 is not only very stable, it is also safer while assembling and dismantling. During vertical assembly, decks can be mounted as assembly decks. Then the frames, ledgers and diagonal braces of the next tower section can be assembled from within the tower structure, like an advance guardrail, providing very effective fall protection.

Other safety benefits:

- Reduced weight means less risk of sprains or strains and lost time – the heaviest part is 18kg

- Craning and repositioning using castors reduces erection and dismantle work, helping to minimise the risk of injury.

Safer assembly with advanced guardrail -

Safe cantilevered walkway around the shoring -

Allround Shoring TG 60 supporting two tunnel boring machines, each weighing 170 tonnes

-

MORE REASONS TO CHOOSE LAYHER

-

ALLROUND SCAFFOLDING

ALLROUND SCAFFOLDING -

TEMPORARY STAIR SOLUTIONS

TEMPORARY STAIR SOLUTIONS -

ACCESSORIES AND SCAFFOLDING COMPONENTS

ACCESSORIES AND SCAFFOLDING COMPONENTS